-

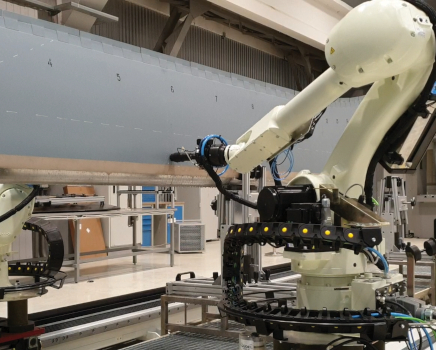

- Overview: The laser scanning and flaw detection bench ROBOSCOP VTM-5000 HELICOPTERS is designed for the non-destructive testing of polymer-composite materials used in aircraft constructions: glider elements, helicopter blades, honeycomb panels It is also applicable in wind power engineering, small-sized shipbuilding, pipe fitting production, etc. All tooling (laser scanner, sensors) selection and change processes are automated.

FEATURES ROBOSKOP VTM-5000 HELICOPTERS

The NDT and laser scanning Roboscope VTM-5000/HELICOPTER is designed for the non-destructive testing of polymer-composite materials used in aircraft constructions: glider elements, helicopter blades, honeycomb panels. It is also suitable for use in wind power engineering, small-scale shipbbuilding and pipe fitting production.

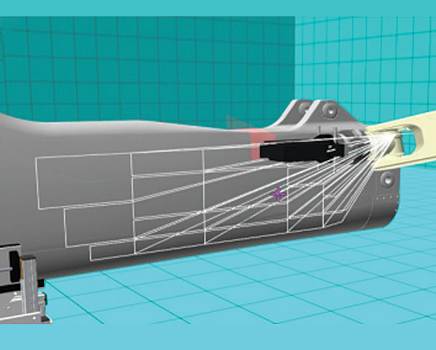

Testing techniques: impedance method, as a basic method for materials with a high attenuation coefficient free vibration method for honeycomb structures eddy-current method for magnetic and ferromagnetic alloys ultrasonic, including shadow, echo-pulse, phased array, laminar methods laser method for geometric parametrs measuring (profilometry)

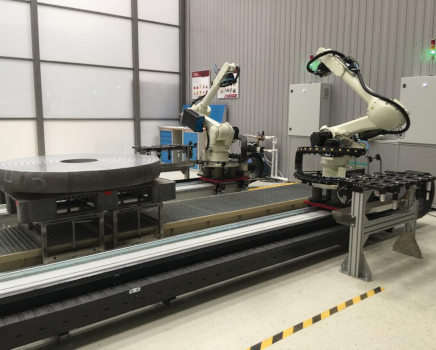

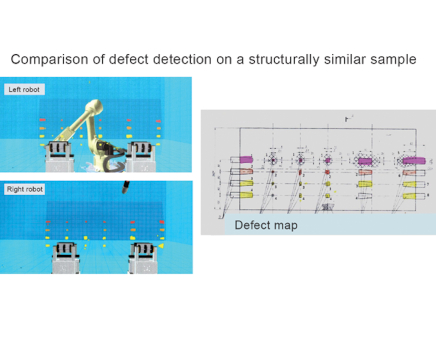

The selection of testing techniques and the choice of transducers are determineted during the initialization stage. All NDT methods are avialable concurrently. The specification of scanning areas, motion paths and testing speed is managed through the CAD application Method Designer. For composite panels, sensitivity adjustment is performed layer by layer, considering the materials physical properties, sush as attenuation. In impedance testing mode, an optimal spectrum of probing signals is automatically configured for each material during the initialization process.

The Roboscope VTM-5000/HELICOPTER scalability allows the testing of parts with varying shapes and sizes and the mechanization criteria are individually defined during the design stage.

Roboscope VTM-5000/HELICOPTER enables the efficient completion of the entire testing process, providing a high-precision flaw map that takes into account all applied techniques. The quantity of roboyic units to be used is determined during the technical task design stage